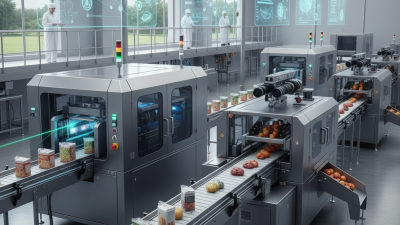

| Metal Detectors |

Identify metal contaminants in food products |

Sensitivity adjustments, multi-frequency detection |

Integration with IoT for real-time monitoring |

| X-Ray Inspection |

Detect foreign objects and product integrity |

High-resolution imaging, 3D modeling |

Automated analysis using AI algorithms |

| Spectroscopy |

Analyze the composition of food products |

Non-destructive testing, rapid results |

Portable devices for on-site testing |

| Thermal Imaging |

Identify temperature anomalies in food |

Real-time analysis, easy reporting |

Integration with predictive maintenance systems |

| Chemical Testing Kits |

Detect chemical contaminants |

Easy to use, quick results |

Advancements in sensitive detection technologies |

| Weighing Scales |

Ensure accurate product weights |

High precision, connectivity options |

Smart scales with automated tracking features |

| Hygiene Monitoring Systems |

Monitor cleanliness of food areas |

Real-time alerts, data logging |

Integration with overall food safety management |

| Vision Inspection Systems |

Ensure quality and packaging integrity |

Machine learning capabilities, 360-degree inspection |

AI-driven pattern recognition |

| Blockchain Tracking Systems |

Traceability of food supply chain |

Immutable records, transparency |

Greater adoption in regulatory compliance |

| Smart Sensors |

Monitor environmental conditions |

Wireless connectivity, cloud data management |

Expansion in smart farming applications |