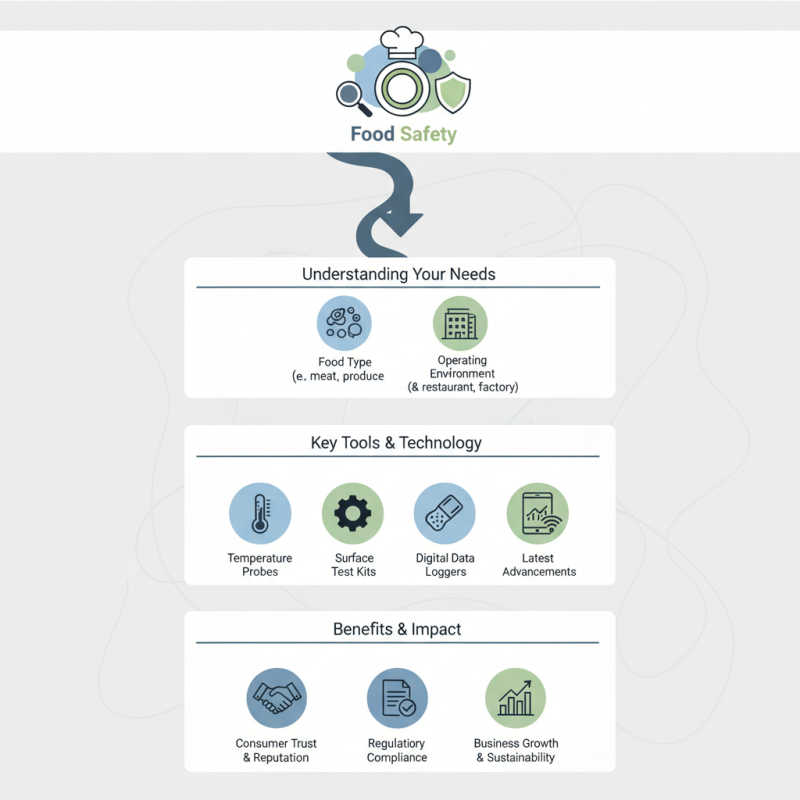

Food Safety Insights

In Eagle’s Advanced Insights Blog, experts share their know-how by keeping you up-to-date with the latest trends to ensure your inspection equipment keeps your products safe. Eagle is an industry leader when it comes to performance and innovation, and we’ll share the news that’s important to you to enhance your quality assurance program.