2026 How to Choose the Right Fruit and Vegetable Processing Equipment?

In the dynamic world of food production, choosing the right fruit and vegetable processing equipment is crucial. Experts emphasize the importance of this selection. Bob Smith, a leading industry analyst, stated, "The right equipment can enhance efficiency and product quality." This highlights the need for careful consideration.

Every operation requires specific machinery tailored to its produce. Factors like volume, type of fruit or vegetable, and intended use matter greatly. For small farms, simple machines may suffice. However, larger manufacturers often need advanced technology for scale and consistency.

Reflecting on choices can be challenging. Sometimes, businesses invest in expensive equipment that does not meet their needs. This can lead to wasted resources and reduced profits. Therefore, understanding your requirements is vital. Ensuring that your fruit and vegetable processing equipment aligns with your goals will pave the way for success.

Understanding the Different Types of Fruit and Vegetable Processing Equipment

When selecting fruit and vegetable processing equipment, it’s crucial to understand the various types available. Each piece serves a specific purpose. For instance, washing machines are essential for cleaning produce efficiently. A well-designed washing system can remove dirt and contaminants effectively.

Another vital category is cutting and slicing machines. These tools can vary greatly in size and function. Some are manual, while others are fully automated. Think about the volume of your production. A small-scale operation may not require large machinery, while a high-output facility certainly will.

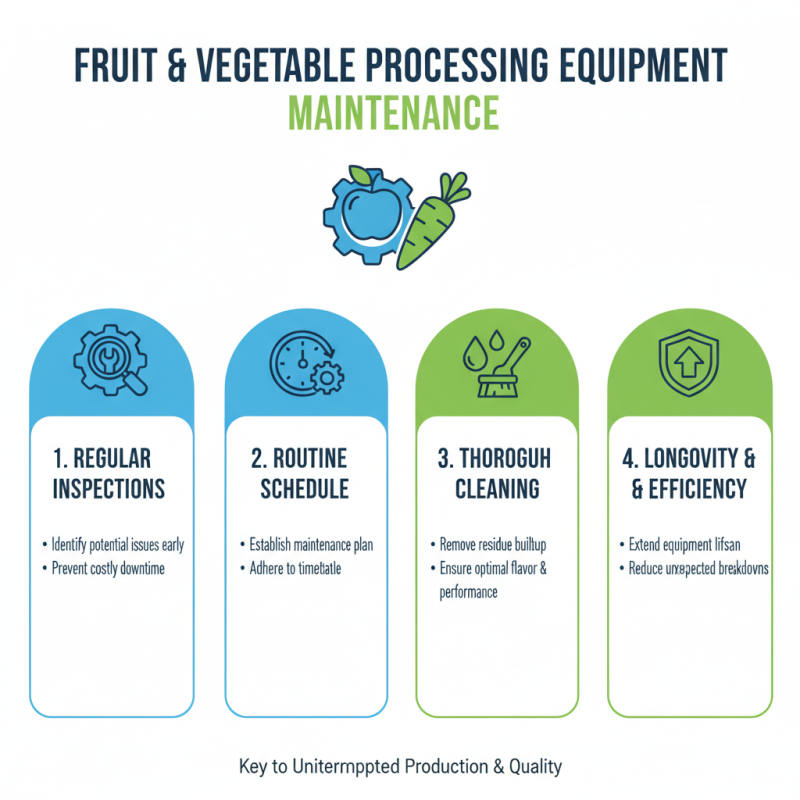

Tips: Always consider energy efficiency. Machines that consume less energy can significantly reduce your operational costs. Also, think about maintenance. Some equipment may require more upkeep than others, which can be a burden. Remember, not all machines are perfect for your needs. Sometimes, it's necessary to adjust your processes based on equipment limitations. Reflect on how each piece complements your overall workflow to ensure a smooth operation.

Assessing Your Production Needs: Volume, Type, and Variety of Produce

When choosing fruit and vegetable processing equipment, it’s important to assess your production needs. Consider the volume of fruits and vegetables you handle. Are you processing small batches or large quantities? High-volume operations require robust machines. These machines ensure efficiency and minimize downtime. They can handle continuous operation without frequent breakdowns.

Next, think about the types of produce you'll be working with. Different fruits and vegetables have unique characteristics. Some might need gentle handling, while others require more robust processing. For example, soft fruits like strawberries are more delicate than hard vegetables like carrots. Understanding these differences can help you pick the right machinery.

Variety is another crucial factor. If you plan to process several types of produce, versatility is key. Some equipment may have limitations. A one-size-fits-all approach doesn't always work in processing. You might end up needing additional machines for specific tasks. Reflect on your current and future needs. Can your equipment adapt as your business grows? Balancing these considerations is challenging, yet essential for success.

2026 Fruit and Vegetable Processing Equipment Assessment

Key Features to Consider When Selecting Processing Equipment

Choosing the right equipment for processing fruits and vegetables demands careful consideration. Key features significantly impact efficiency and quality. First, assess the processing capacity. Equipment should match your production needs. A smaller scale operation may not require large machines. It is crucial to size accordingly.

Next, think about the technology used. Advanced machinery can enhance productivity. However, they often come with complex operations. User-friendliness is essential. If staff struggle to operate the equipment, productivity can suffer. Consider ease of maintenance as well. Simplified servicing can prevent unexpected downtimes.

Materials used in construction are also vital. Food-safe materials ensure safety and compliance. Equipment should withstand wear and tear but can be a significant investment too. Balancing cost and quality is challenging. Lastly, evaluate energy efficiency. It affects operating costs in the long run. Sometimes, the most efficient output comes from unexpected choices. Rethink your initial preferences to find the best fit.

Evaluating Cost-Effectiveness and Return on Investment

When selecting fruit and vegetable processing equipment,

cost-effectiveness is key. A study from the Food Processing Suppliers Association indicates that

equipment efficiency can improve output by up to 30%.

However, many businesses overlook maintenance costs,

which can lead to unexpected expenses. Regular checks are critical to avoid costly downtime.

Return on investment (ROI) is influenced by various factors. According to a report from the USDA,

improved processing technology can yield an ROI of 25%

over five years. However, operators need to analyze their specific needs. Investing in equipment without a

thorough evaluation can lead to regrets. The right equipment should match production goals and budget constraints.

Real-world experiences show that merely focusing on purchase price

can lead to issues. For instance, low-cost machinery may require frequent repairs. This drives up long-term costs.

In contrast, investing in more reliable equipment could enhance productivity over time. Balancing initial expenses

with potential benefits is essential for long-term success.